FRA 145/S EMC Screened Multicore

Applications :

- Multicore cable with improved fire performance and very high resistance to temperature designed for internal wiring in lamps, heating appliances and distribution boxes in apparatus, mechanical and plant engineering, etc. Used for fixed and flexible application in dry, humid and wet rooms.

Standards :

- IEC 60754-1, EN 50267-2-1 (halogen free)

- IEC 60754-2, EN 50267-2-2 (no corrosive gases)

- NES 02-713, NFC 20-454 (no toxic gases)

- IEC 61034, EN 50268-2 (low smoke density)

- IEC 60332-1, EN 50265-2-1 (flame retardant)

- IEC 60332-3, EN 50266-2, NF C 32-070 (non-flame propagating)

- DIN 51900 (low fire load)

|

|

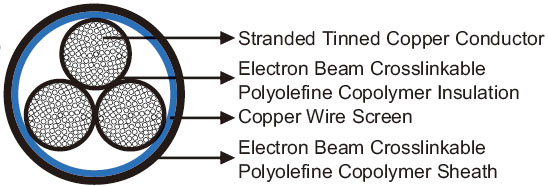

Construction :

- Conductors : Class 5 stranded tinned copper to IEC60228/VDE 0295.

- Insulation : Electron beam crosslinkable polyolefine copolymer.

- Screen : Copper wire screen.

- Sheath : Electron beam crosslinkable polyolefi ne copolymer.

Electrical Characteristics at 20 °C :

-

Nominal Conductor Cross Section mm² 0.50 0.75 1.0 1.5 2.5 4.0 6.0 Maximum Conductor Resistance Ω/km 40.1 26.7 20.0 13.7 8.21 5.09 3.39 Voltage Rating V 300/500V (≤1mm²); 450/750V (≥1.5mm²)

Mechanical and Thermal Properties :

- Minimum Bending Radius : 4xOD (Static); 6xOD (Flexing).

- Temperature Range : -55℃ ~+145℃ (Static); -40℃ ~+120℃ (Flexing).

- Short Circuit Temperature : +280℃.

Dimensions and Weight :

| No. of cores& Nominal Conductor Cross Sectional Area No.×mm² |

Number and Nominal Diameter of Strands No./mm |

Nominal Insulation Thickness mm |

Nominal Overall Diameter mm |

Nominal Weight kg/km |

| 1×0.5 | 16/0.20 | 0.5 | 3.7 | 23 |

| 2×0.5 | 16/0.20 | 0.5 | 5.6 | 45 |

| 3×0.5 | 16/0.20 | 0.5 | 6.1 | 59 |

| 4×0.5 | 16/0.20 | 0.5 | 6.7 | 72 |

| 5×0.5 | 16/0.20 | 0.5 | 7.3 | 86 |

| 6×0.5 | 16/0.20 | 0.5 | 7.9 | 102 |

| 7×0.5 | 16/0.20 | 0.5 | 8.4 | 118 |

| 8×0.5 | 16/0.20 | 0.5 | 9.0 | 133 |

| 10×0.5 | 16/0.20 | 0.5 | 10.0 | 157 |

| 12×0.5 | 16/0.20 | 0.5 | 10.0 | 164 |

| 1×0.75 | 24/0.20 | 0.6 | 4.0 | 28 |

| 2×0.75 | 24/0.20 | 0.6 | 6.7 | 66 |

| 3×0.75 | 24/0.20 | 0.6 | 7.1 | 78 |

| 4×0.75 | 24/0.20 | 0.6 | 7.7 | 94 |

| 5×0.75 | 24/0.20 | 0.6 | 8.5 | 113 |

| 6×0.75 | 24/0.20 | 0.6 | 8.9 | 132 |

| 7×0.75 | 24/0.20 | 0.6 | 9.9 | 158 |

| 8×0.75 | 24/0.20 | 0.6 | 10.6 | 181 |

| 10×0.75 | 24/0.20 | 0.6 | 11.5 | 209 |

| 12×0.75 | 24/0.20 | 0.6 | 11.5 | 219 |

| 14×0.75 | 24/0.20 | 0.6 | 12.2 | 251 |

| 16×0.75 | 24/0.20 | 0.6 | 12.9 | 279 |

| 19×0.75 | 24/0.20 | 0.6 | 14.5 | 347 |

| 21×0.75 | 24/0.20 | 0.6 | 15.3 | 385 |

| 1×1 | 30/0.20 | 0.6 | 4.2 | 33 |

| 2×1 | 30/0.20 | 0.6 | 7.2 | 79 |

| 3×1 | 30/0.20 | 0.6 | 7.7 | 89 |

| 4×1 | 30/0.20 | 0.6 | 8.3 | 113 |

| 5×1 | 30/0.20 | 0.6 | 9.0 | 134 |

| 6×1 | 30/0.20 | 0.6 | 9.5 | 156 |

| 7×1 | 30/0.20 | 0.6 | 10.9 | 187 |

| 8×1 | 30/0.20 | 0.6 | 11.4 | 218 |

| 10×1 | 30/0.20 | 0.6 | 12.5 | 253 |

| 12×1 | 30/0.20 | 0.6 | 12.5 | 266 |

| 1×1.5 | 30/0.25 | 0.6 | 4.8 | 43 |

| 2×1.5 | 30/0.25 | 0.6 | 8.4 | 105 |

| 3×1.5 | 30/0.25 | 0.6 | 8.9 | 119 |

| 4×1.5 | 30/0.25 | 0.6 | 9.9 | 163 |

| 5×1.5 | 30/0.25 | 0.6 | 10.7 | 183 |

| 6×1.5 | 30/0.25 | 0.6 | 11.5 | 219 |

| 7×1.5 | 30/0.25 | 0.6 | 12.7 | 273 |

| 8×1.5 | 30/0.25 | 0.6 | 13.7 | 305 |

| 10×1.5 | 30/0.25 | 0.6 | 15.0 | 309 |

| 2×2.5 | 50/0.25 | 0.7 | 9.9 | 157 |

| 3×2.5 | 50/0.25 | 0.7 | 10.5 | 198 |

| 4×2.5 | 50/0.25 | 0.7 | 11.5 | 236 |

| 5×2.5 | 50/0.25 | 0.7 | 12.8 | 287 |

| 7×2.5 | 50/0.25 | 0.7 | 15.5 | 430 |

| 4×4 | 56/0.30 | 0.8 | 13.2 | 317 |

| 5×4 | 56/0.30 | 0.8 | 14.5 | 376 |

|

|

|

|

|

Impact Resistant |

Highly Flexible |

Weather Resistant |

UV Resistant |

Low Toxicity |

|

|

|

|

|

Flame Retardant NF C32-070-2.1(C2) IEC 60332-1/EN 50265-2-1 |

Fire Retardant NF C32-070-2.2(C1) IEC 60332-3/EN50266 |

Zero Halogen IEC 60754-1/NF C20-454 EN 50267-2-1 |

Low Smoke Emission IEC 61034/NFC20-902 EN 50268/NF C32-073 |

Low Corrosivity EN 50267-2-2/NF C32-074 IEC 60754-2/NF C20-453 |